Our team of expert scientists and engineers in collaboration with Europian companies has created a groundbreaking invention called VORTEX®. This innovative plasma vortex technology is designed for the disposal of all types of carbon-containing raw materials. The energy generated during the destruction of the substance is harnessed for the production of secondary energy resources:

VORTEX®

Plasma vortex technology - multi-fuel boiler unit on all types of carbonaceous raw materials and the production of electrical and thermal energy.

This technology can be implemented in a multi-fuel boiler unit that can handle different types of fuel. The key feature of VORTEX® is its plasma vortex combustion system that ensures complete combustion of the fuel, resulting in high energy conversion efficiency and low emissions. This technology can be used in various industries, including power generation, waste-to-energy and industrial heating. With its versatility in handling different types of fuel and high energy conversion efficiency, VORTEX® is a promising solution for sustainable energy production.

VORTEX® is the result of years of extensive research and development. It is designed to be a highly efficient and environmentally friendly solution for managing carbon-containing materials. The technology is based on plasma vortex technology, which is capable of completely destroying any carbon-containing material without producing harmful emissions.

The VORTEX® technology is ideal for a wide range of applications, including waste management, industrial heating and energy production. Its ability to generate both thermal and electrical energy from a wide range of carbon-containing raw materials makes it a superior choice for sustainable energy production.

Our team of proficient scientists and engineers is proud to have developed the VORTEX® technology, which has the potential to revolutionize the energy sector and contribute to a cleaner and more sustainable future.

VORTEX®

VORTEX® is the result of combination of the best and most affordable modern technologies for the disposal of carbon-containing raw materials. Our innovative technical device aligns with all the principles of modern innovative technology:

- Waste-to-energy

With VORTEX®, waste-to-energy conversion becomes possible. The device is capable of utilizing any carbonaceous substance and converting it into heat and electricity. It simultaneously helps to manage waste efficiently and also generates sustainable energy resources.

- CO2 elimination

The technology also addresses the issue of CO2 elimination as VORTEX® does not release any harmful or toxic substances during the process. Moreover, the ash residue that remains after the process is environmentally inert.

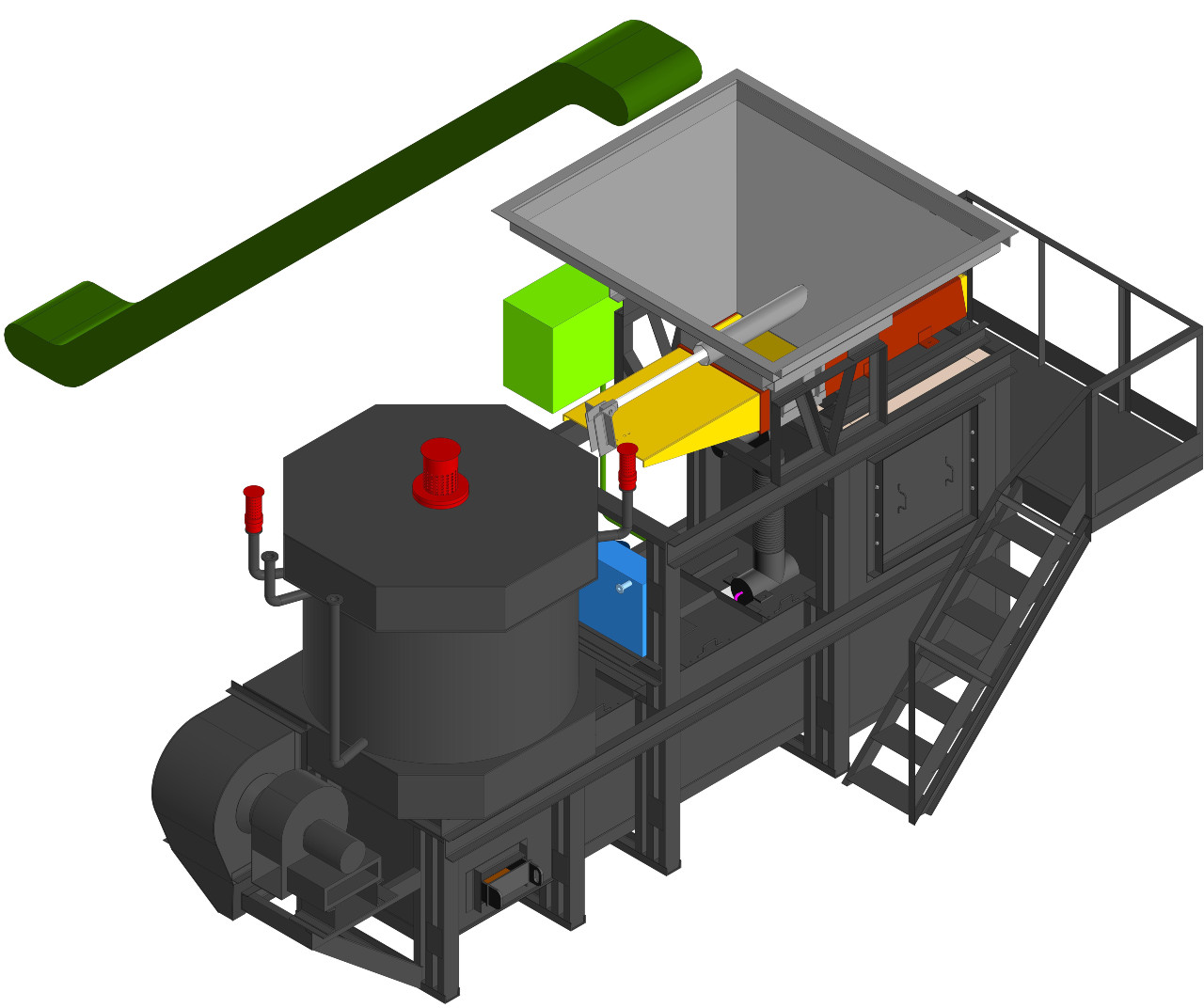

- Mobility

VORTEX® is designed to be highly mobile, compact and efficient, making it suitable for decentralized mass application. This feature allows the device to be easily deployed to various locations to manage waste and produce energy on-site.

- Automation

Our VORTEX® device is fully automated, which simplifies waste management and energy recovery. With efficient remote control, the process can be monitored continually, ensuring emissions are within environmental standards. The technology is future-ready and designed to be highly adaptable to meet the changing needs.

Our team is proud to present VORTEX® as a revolutionary solution that addresses the challenges of waste management and energy production, while maintaining environmental sustainability.

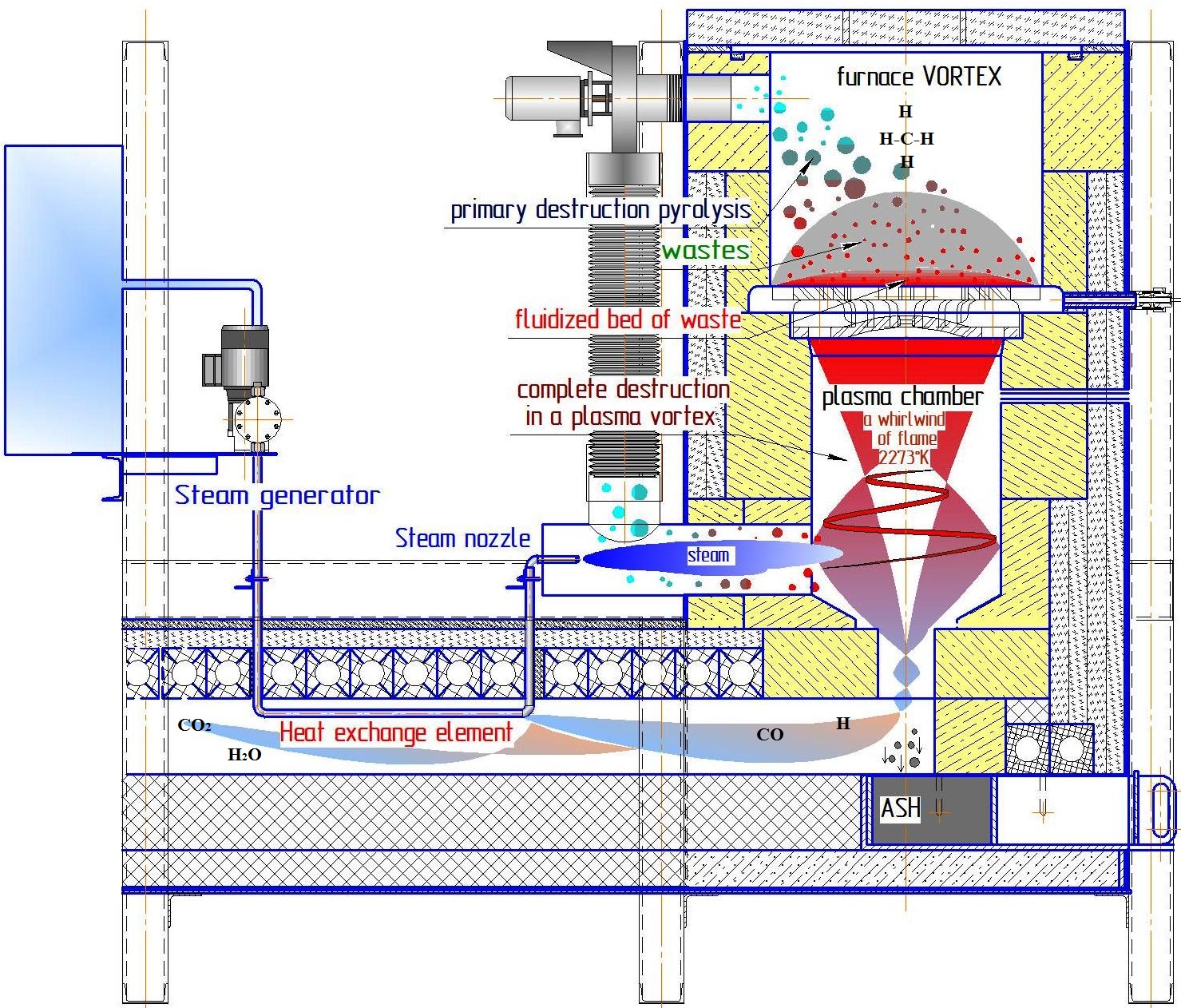

Plasma vortex technology is the foundation of our VORTEX® plant, where a cylindrical structure is created in a reactor to generate a plasma vortex. This technology enables the destruction of organic substances in the absence of oxygen or any other oxidant by plasma-chemical reactions in the gas vortex.

The plasma vortex technology is characterized by a high temperature of the substance which the reaction proceeds. In VORTEX®, the substance is in a state of cold plasma, which makes the technology more efficient and sustainable. This high-temperature process results in thorough destruction of organic waste, producing electricity and other valuable substances.

The plasma vortex technology has several advantages, including complete destruction of organic waste, safe disposal of toxic waste and reduction of greenhouse gas emissions. The process improves operational safety, reduces maintenance costs and increases energy efficiency.

Plasma vortex technology utilized in VORTEX® is highly efficient, sustainable and environmentally friendly. The advanced technology is designed to revolutionize the way how we manage waste, providing safe and sustainable solutions to the growing environmental challenges faced by modern society.

Energy efficiency

The VORTEX® device is designed to be highly energy efficient and autonomous. The device creates a significant excess of thermal energy, which can be used as a secondary energy resource. This thermal energy is harnessed through heat exchangers that are integrated into the VORTEX® technical device.

By converting the excess thermal energy into steam, it can be used to generate additional electricity or provide heat to nearby buildings, becoming a secondary source of energy. This results in further energy savings, making VORTEX® an environmentally friendly and sustainable solution for waste management.

Additionally, the VORTEX® device uses a closed-loop system that reduces energy consumption during operation. The system recycles excess energy in the form of gases and by-products, reducing the overall energy needed to sustain operation.

VORTEX® device is an energy-efficient solution for waste disposal that harnesses excess thermal energy to generate electricity and provide heat through its closed-loop system. This innovative technology ensures that waste is managed in a sustainable and environmentally friendly manner while generating valuable energy resources.

European programs aimed at reducing waste and its disposal include:

- Circular Economy: a program of the European Commission aimed at creating an economy with no waste. This includes utilizing resources in a more efficient and environmentally sustainable manner, as well as developing new business models and promoting innovative waste management strategies.

- Green Waste Management: a program developed by the European Union that aims to increase the efficiency of waste management in Europe through the implementation of new waste disposal technologies and methods.

- Bioeconomy: a program aimed at increasing the utilization of biological waste and creating new biological sources of energy. It also promotes the improvement of environmental characteristics of production processes through the use of bio-waste.

- Zero Waste: a program aimed at creating strategies, technologies and methods to reduce the amount of waste produced. It also takes into account public opinion and provides education on environmentally friendly lifestyles.

These programs are under the auspices of the European Union as part of the implementation of a comprehensive waste management strategy in Europe. They are designed to reduce the amount of waste produced and increase the efficiency of its disposal to protect the environment and improve the quality of life for the population.

Every piece of waste that you throw away today has the potential to become a source of warmth and light thanks to the revolutionary VORTEX® technology.

Rather than leaving these materials in landfills, they can be valuable resources that help us to reduce our dependence on oil and coal and protect our planet from pollution. Essentially, VORTEX® enables us to convert waste into valuable energy that can be used to provide warmth and light for our homes and workplaces. This is not only an innovative solution to waste problem, but also a step forward towards a more sustainable future.

By choosing our unique VORTEX® technology, you are advancing the world by making it cleaner, brighter and more hospitable place.

Contact us

Please feel free to contact us

You are very important to us, all information received will always remain confidential.